The AudioWorks

Aardvark Ethernet Noise Isolation

Aardvark Ethernet Noise Isolation

Couldn't load pickup availability

"This deceptively simple device has become an absolutely indispensable part of my streaming infrastructure."

Noise is the fiercest enemy of the most enjoyable aspects of music reproduction.

Micro dynamics, sense of space, detail, atmosphere... sheer delight.

Name those subtle features in music that open your own personal door to pleasure and all of them are affected by noise.

From the dawn of its existence, noise has been an enemy of hi-fi.

Today in the Digital Era, noise has become “The” enemy.

It not only affects silences. Noise also corrupts the process of transporting and recovering data itself.

In a way, noise has matured. It is no longer a “hum" or "hiss” in your speakers.

It has become something more complicated and much more difficult to deal with.

Once noise invades the sacred ground plane of a digital system, it seems to be everywhere.

Noise is very difficult to eliminate because it is inherent to some components, and since all components are interconnected, if one component has noise, all connected components can be affected.

The only solution is to confine it wherever it resides. Keep it from polluting the most critical components of the audio system.

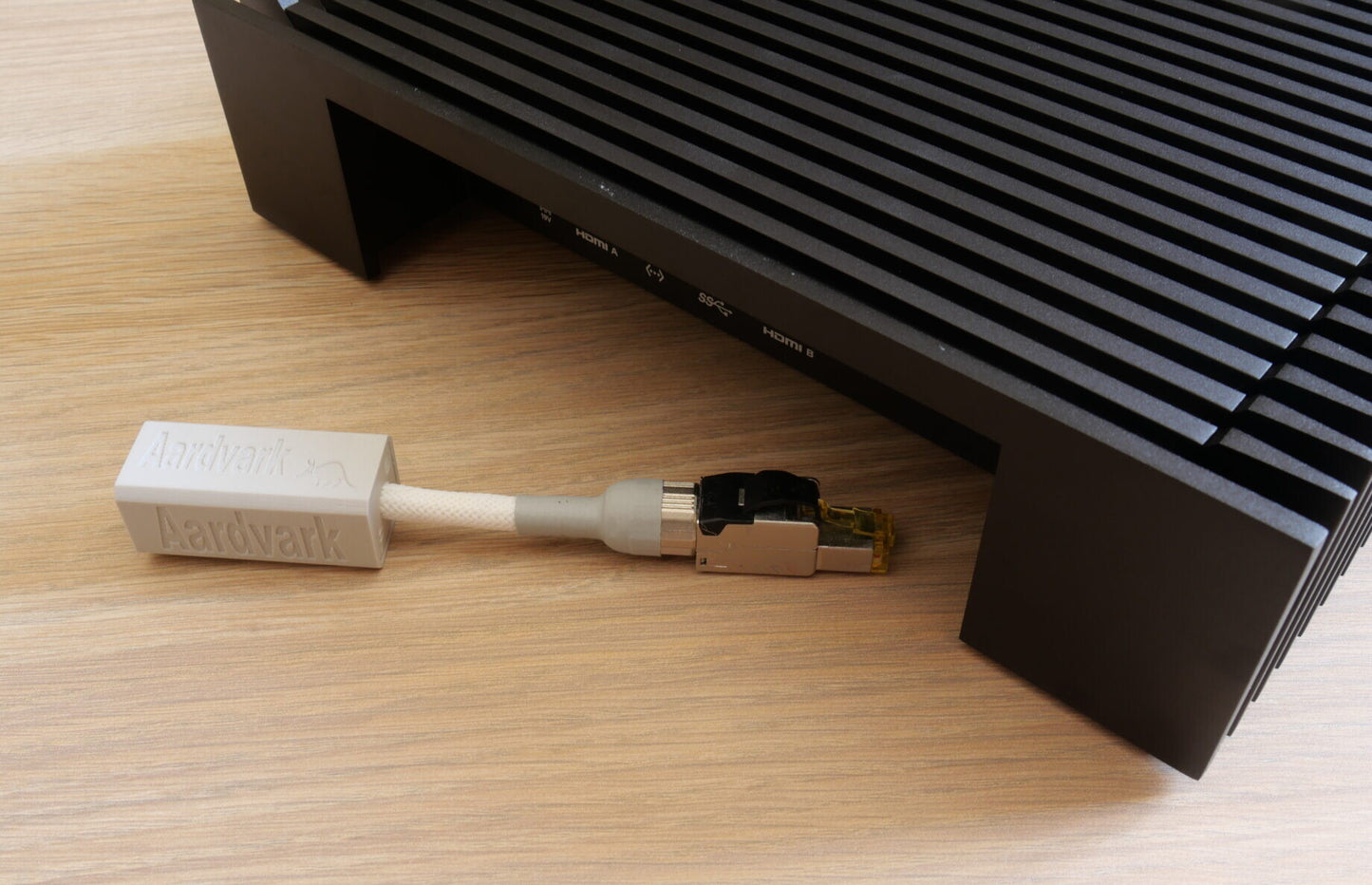

Modern digital high-end audio means streaming, local (LAN) or remote (WAN), and in both cases that involves a router, or a switch, or both of them.

A switch is noisy, and a router is even noisier.

But not only them, a local server with all its processes and clocks running is noisy too.

Not to mention the local network itself.

Truth is, in all of its shapes and manifestations, noise simply denies silence.

And silence, is a vital part of music.

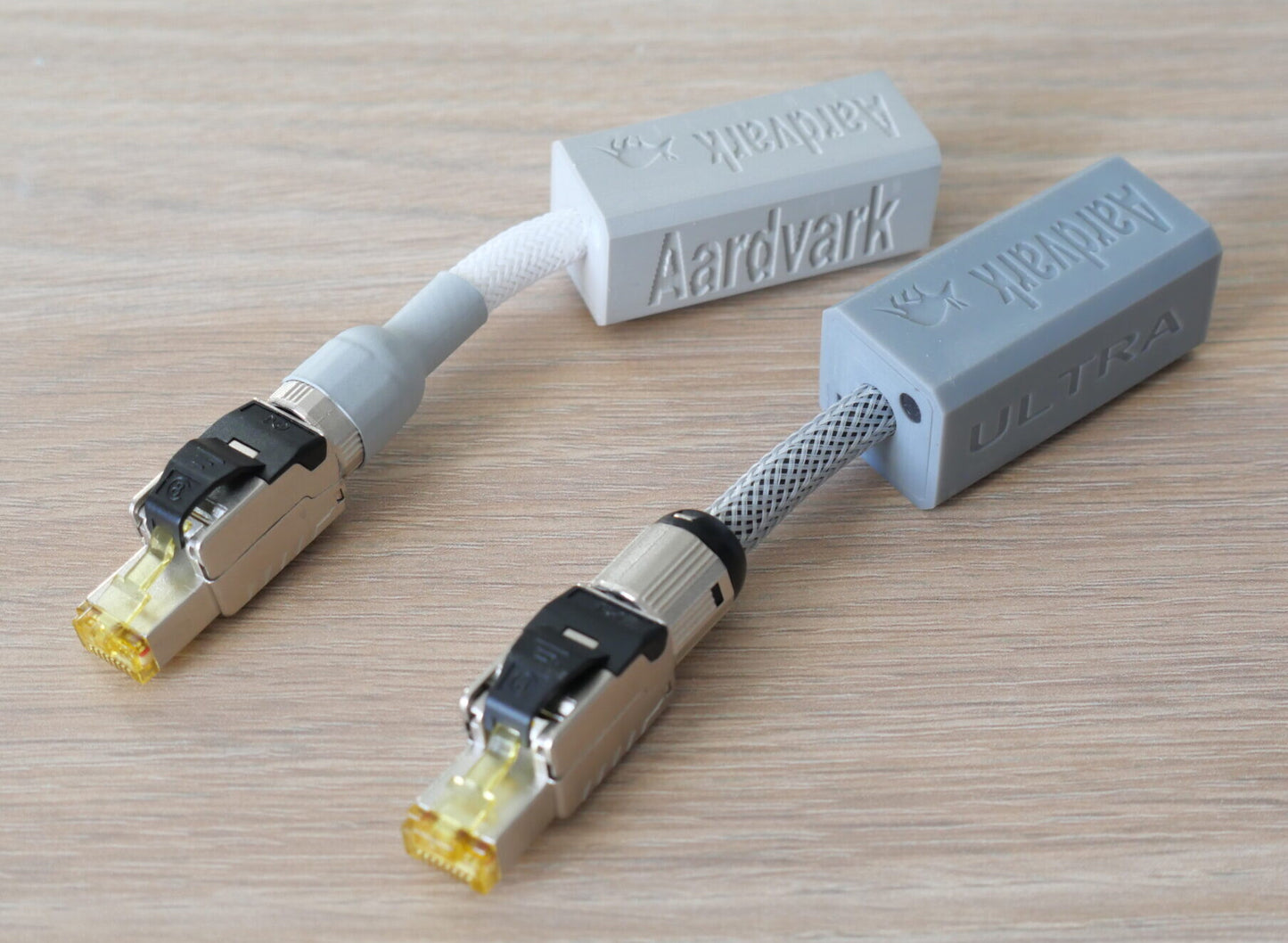

The Classic

This is where galvanic isolation comes into play.

Isolation is the antidote.

Perfect isolation comes in the form of a device that has a RJ45 male plug in one extreme and, to protect the ground plane, a transformer coupled female jack in the other .

Two coils, inducting data to each other and presenting zero electrical conductivity between them.

As simple as that.

A passive device, no outboard power supply that potentially adds additional noise or inconvenience of its own.

All this has to be done properly to obtain the remarkable results that are possible.

As is so often the case, the simpler something is, more critical is the quality of the elements involved. It’s a reasonable counterpart.

Also, every step counts, every step plays a role in this process.

First you need a very good Ethernet micro transformer with a specific impedance & desired bandwidth.

Then you need to hard wire it (no PCB involved, please) by silver alloy soldering it to a very highly quality cable, whose natural shielding has been carefully incremented.

You also find the perfect shielded RJ45 connector for the task. You try many of them.

And to connect it to the assembly, again, hard wiring & silver alloy soldering, as wherever there is a connection.

You do all this by hand.

One by one.

Then you place the resulting device into its vibration damped container to ensure integrity and long term performance.

Then you develop and test a few dozen architectures that accomplish the exact same thing in subtly different ways.

And you listen their effects on the music that you love for hours. And months.

Then you smile, when you find the one that works the best.

You smile because you know that you have a solution to the problem.

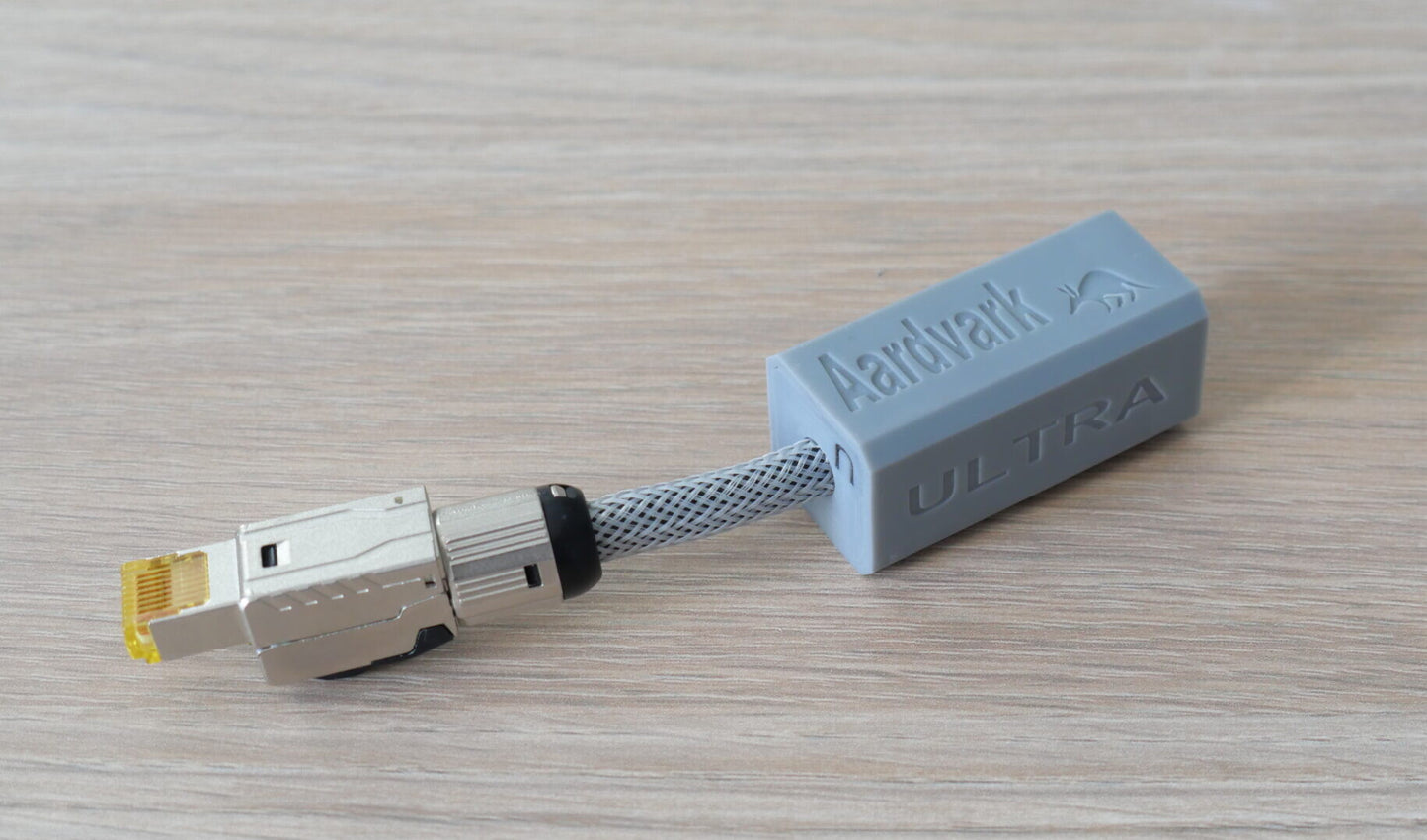

The ULTRA

The ULTRA means doing the same job the Classic does, but taking it to the highest possible standard, regardles of labor, time, or resources involved, and setting the cleanest possible path between the components to be connected.

It implements a high quality transformer, in a copper and mu-metal extremely heavy shielded cable and enclosure combo. As the Classic, it is hard-wired, silver alloy hand soldered, every wire, one by one.

The reason

As said before, noise is the basic enemy, and there are three different noise sources to be addressed.

One. The intrinsic noise of the connected devices, as ALL of them have their amount of noise, bigger or smaller, because digital needs clocks to work, and every oscillator is intrinsically noisy.

As noise travels through the ground plane, and all devices have their own amount of noise, it is important then to confine that noise where it is and not allow it to pollute the ground plane.

Hence a high-quality transformer. No electrical continuity.

Two. The signal path itself. Should be as clean, direct, and as high quality connected as possible. In that sense, boards, friction connections, and interconnecting pieces of any kind are avoided. That is the reason for the hard-wired connection and silver alloy soldering.

These two issues are being taking care of already very well by the Classic. As good as the ULTRA.

But there is a third issue that the ULTRA takes special care of, the external EMI.

As mentioned before, electronic components, and high-end music systems are no exception, are plagued by electromagnetic interference. This insidious type of noise floats around all electrical devices.

The Classic is very well shielded, no doubt about that.

But with its extreme, meticulous and time-demanding, heavy copper and mu-metal shielding, the ULTRA takes EMI protection to another level.

It takes it as close to the edge of infeasible as possible. So, outside noise stays absolutely outside.

This way, the ULTRA addresses all three issues in its particular, and most effective, possible way.

The process

Many manufacturers, industrial and semi-industrial, even the best, implement high-grade field assembly RJ45 plugs that are excellent for fast repairing on the field. That means fast termination, but “fast” doesn’t mean “best”. In this case fast means wires hooked to a small board, board that in time is hooked into the plug. In other words, friction connection/contact in every conductor. That is the procedure even with the best of plugs manufacturers, even the most famous ones.

On top of that no extra shielding to EMI but the provided by the plug manufacturer itself.

In the ULTRA, RJ45 plugs are internally coated with heavy EMI shielding, and then hard-wired and silver alloy hand soldered, every wire, one by one.

The same procedure is performed on the transformer end of the cable.

No intermediate connectors, no boards or friction contacts.

It takes many hours to manufacture just one of them.

That is why Aardvark products are artisanal, and will always stay artisanal. There is no way to manufacture them in an industrial level of any kind.

Share